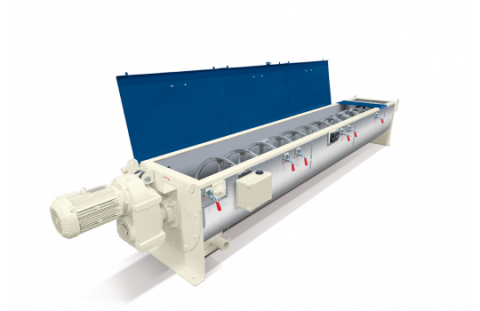

Voedselverwerkingsmachines

In de categorie Voedselverwerkingsmachines vindt u een uitgebreid aanbod productinnovaties met productinformatie en technische specificaties. Kom in contact met leveranciers die actief zijn in deze categorie en vind de juiste oplossing voor uw project. Kunt u het product niet vinden? Ga dan naar de categorie machines, bekijk leveranciers op deze pagina of gebruik de zoekfunctie van Products4Engineers.