Bulldog Conveyor Belt Misalignment & Rip Detection System

detect a misalignment

Beschrijving

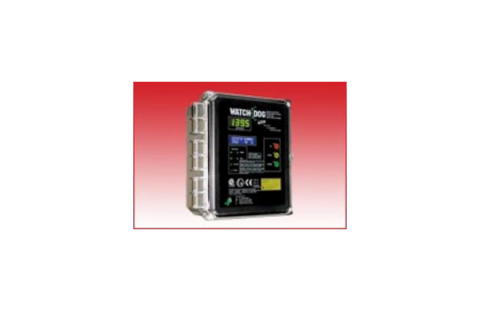

The Bulldog alignment and rip detection switch is an electro-mechanical system designed to detect dangerous misalignment of the conveyor and also

detection of belt tear damage.

The switch wildetect horizontal misalignment of belts l when contact is made with the roller, the roller arm will be forced to pivot by the belt activating a switch at 15º to trigger an alarm, and 30ºto trigger a shut down procedure of the conveyor. The sensors are usually installed in pairs on opposite sides of the belt.

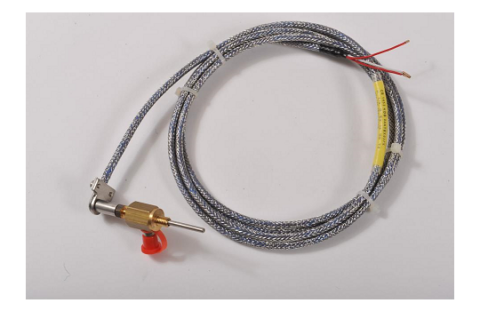

A steel flexible wire is set below the running conveyor belt approx 20-30mm attached by a rare earth magnet at each end. If the belt is ripped or damaged the wire is pulled away releasing the magnet connection which in turn will activate a switch.

Heb je vragen over dit product?

- Vragen over prijs, leverbaarheid en/of verkooppunten

- Vragen over technische specificaties en gebruik

- Vragen over geschiktheid voor jouw project of toepassing

De meeste leveranciers reageren binnen één werkdag.

Productdetails

- Ref. nummer

- #62953

- Leverancier

- Mullerbeltex B.V.

- Merk

- Mullerbeltex B.V.

- Categorie

- Productieapparatuur (elektronica)